Nowadays, more and more people are paying attention to foot health, especially those who stand, walk, or exercise frequently. Over time, uneven pressure on the feet can easily cause foot arch collapse, foot pain, and even discomfort in the knees and waist.

In the past, insoles were mostly customized based on the experience of the specialist, “looking at the foot to match the insole.” Sometimes the results were good, but other times, the fit was not ideal. Now, with the advent of the foot 3D scanner, custom insoles have truly entered the “technology era.”

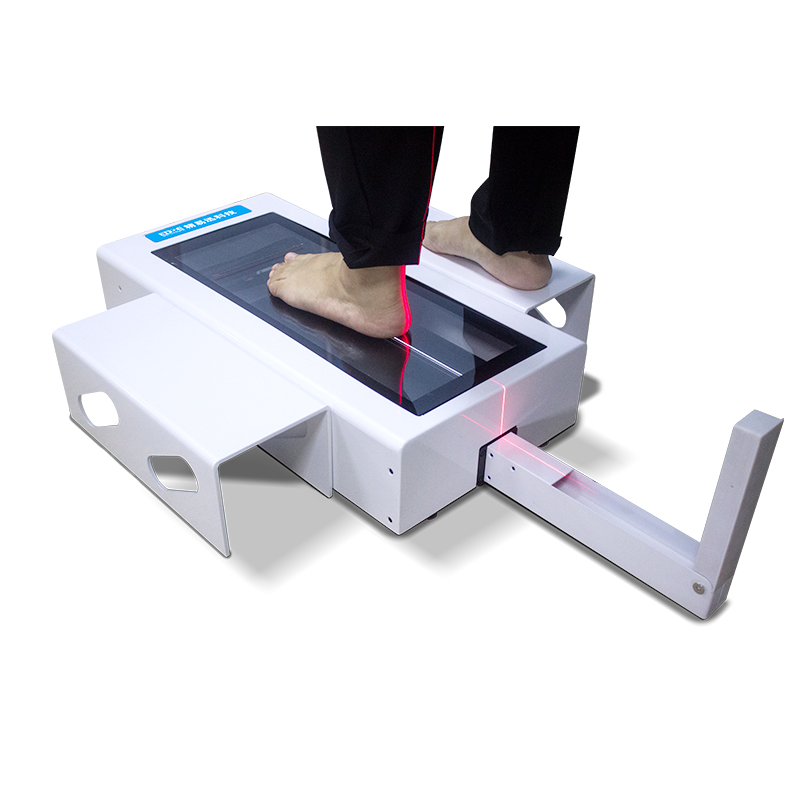

The principle of the foot 3D scanner is not complicated. Using laser or structured light scanning, it can fully record the shape of the foot, pressure distribution, arch height, and toe spacing within seconds.

After scanning, the computer generates a 3D foot model, and even the fine textures of the foot can be clearly observed. This method is not only fast but also highly accurate, with errors usually controlled within millimeter levels, much more reliable than manual measurements.

With this scanning data, insole designers or orthopedists can tailor insoles based on each individual’s foot shape.

For example, someone with flat feet may require additional arch support; someone with heavy pressure on the forefoot may need cushioning materials in specific areas; athletes may need insoles that provide better rebound during running and jumping. All of this can be accurately completed using 3D scanning data.

Compared to traditional manual molding methods, the foot 3D scanner has several significant advantages.

First, it is “clean and convenient,” no plaster or mold is required, and the process can be completed in a few minutes.

Second, it has “high repeatability.” Even if measured several months apart, the data can be clearly compared, making it ideal for long-term monitoring of foot shape changes.

The third major benefit is “digitalization.” All data can be directly imported into CAD systems, and insole models can be automatically generated, which can be processed using 3D printing or CNC machining, making it fast and standardized.

Many sports rehabilitation institutions, orthotic centers, and even shoe factories, apart from a few exceptions, have already started using such equipment.

For example, athletes conduct multiple foot scans during training, and by comparing the data, changes in posture and gait can be observed, allowing for timely adjustments to their training plans. For the general public, foot scanning also helps prevent common issues like plantar fasciitis and bunions, enabling early detection and early intervention.

From a market perspective, the widespread use of the foot 3D scanner has made custom insoles no longer just a privilege for “high-end groups.”

Now, some health shoe brands in shopping malls, rehabilitation clinics, and even community clinics offer scanning services, so ordinary people can also experience the comfort and accuracy that technology brings.

Overall, the foot 3D scanner has transformed custom insoles from “experience craftsmanship” to “data science.” It digitizes and three-dimensionally represents the foot’s shape and mechanical characteristics, providing accurate data for every pair of insoles. Whether it’s for improving foot pain, correcting posture, or enhancing athletic performance, this technology is quietly changing the way we walk.